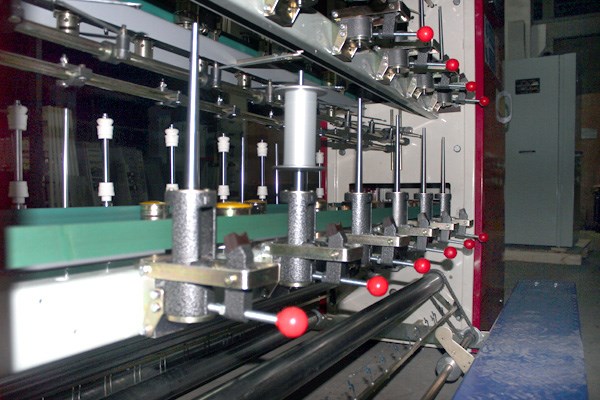

GCM-2000B Covering Machine

|

Model of equipment |

Unit of measurement |

GCM-2000B 192 Spindle covering machine |

GCM-2000B 216 Spindle covering machine |

GCM-2000B 208 Spindle covering machine |

|

Norm of machine |

||||

|

Seucture of machine |

Dual-face dual-layer |

Dual-face dual-layer |

Dual-face dual-layer |

|

|

Number of coiling layer |

Layer |

2 |

2 |

2 |

|

Number of wharve layer |

Layer |

2 |

2 |

2 |

|

Maximum coiling number of single covering |

Position |

192 |

216 |

208 |

|

Maximum coiling number of dual covering |

Position |

96 |

108 |

96 |

|

Number of node |

Node |

8 |

9 |

8 |

|

Number of ingot per node |

Position |

24 |

24 |

25 |

|

Out-form dimension(L×W×H) |

mm |

16400×1300×2030 |

18200×1300×2030 |

16800×1300×2030 |

|

Total weight of equipment |

kg |

4500 |

5000 |

4500 |

|

Spindle |

||||

|

Number of spindle |

Spindle |

192 |

216 |

208 |

|

Type of spindles |

Fixed straight type/fixed conic type |

Fixed straight type/fixed conic type |

Fixed straight type/fixed conic type |

|

|

Distance between spindles |

mm |

270 |

270 |

260 |

|

Mechanical spindle speed |

rpm |

18000 |

18000 |

18000 |

|

Twisting direction of spindle |

S/Z |

S/Z |

S/Z |

|

|

Range of twisting degree |

Twist/m |

200-3500 |

200-3500 |

200-3500 |

|

Capacity of wrapped filament |

g |

450-650 |

450-650 |

450-650 |

|

Wrapped filament bobbin |

Φ84×Φ36×140 |

Φ84×Φ36×140 |

Φ84×Φ36×140 |

|

|

Coiling |

||||

|

Out-form of coiling |

Double-cone integration |

Double-cone integration |

Double-cone integration |

|

|

Out-form dimension of coiling |

mm |

Φ180×190 |

Φ180×190 |

Φ180×190 |

|

Size of coiling tube |

mm |

Φ68×218 |

Φ68×218 |

Φ68×218 |

|

MAximum coiling capacity |

g |

≤1500 |

≤1500 |

≤1500 |

|

Coiling formation |

Mechanical formation/computerized formation |

Mechanical formation/computerized formation |

Mechanical formation/computerized formation |

|

|

Draftiong,electric and power |

||||

|

Drafting range |

Multiple |

1.5-6 |

1.5-6 |

1.5-6 |

|

Power of the motor of the upper spindle |

kw |

5.5 |

5.5 |

5.5 |

|

Power of the motor of the lower spindle |

kw |

7.5 |

7.5 |

7.5 |

Model GCM-2000B covered -yarn machine is specially aimed at the elastic fabrics and applicable for the production of polyamide,polyester, cotton yarn etc.covered yarns of different norms, with the raw material application range at 70D-600D.It holds a lower energy consumption and an extremely high productivity and its technical features stay at a great volume of wrapped filament, up to 1KG without joint, and the reduction of silk-on-tube-change process which used to be frequently done by the operator, enhancing the yarn quality and also reducing the operation.